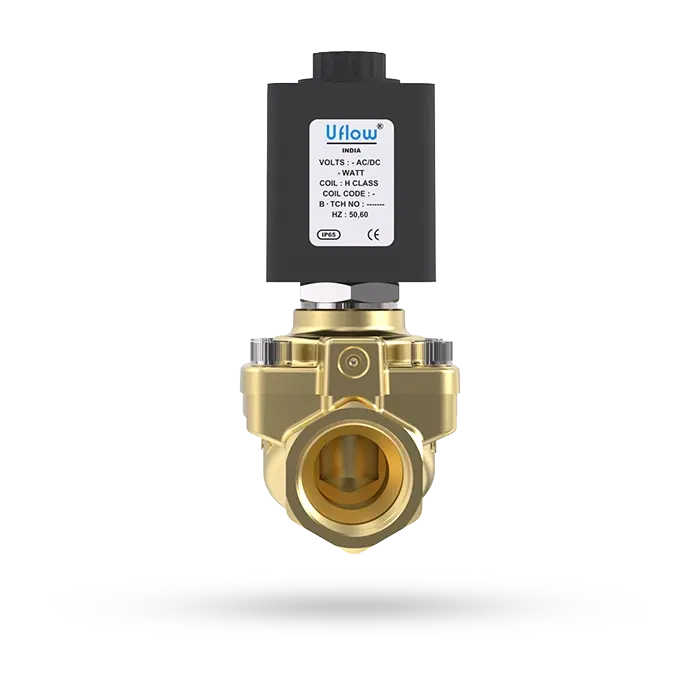

Port

¾” & ½” (Available BSP / BSPT / NPT - (F))

End Connection

Screwed

Body Material

SS ASTM A351 Grade CF8 / CF8M ,Forged Brass

Diaphragm

| PUR | -10°C to 50°C |

Circumstance Temp

-10°C to 70°C

Media

Air

Main Features

Internal Parts are in superior corrosion resistance steel, (Equivalent to SS316L) Suitable for Food Industries, Pharmaceuticals, Chemical application & Highly corrosive environment.

Operating Voltage & Power Consumption

| 230AC | 12DC | 24DC | 110VAC |

| 10W | 10W | 10W | 10W |

Other Specification Data

Available on Request.

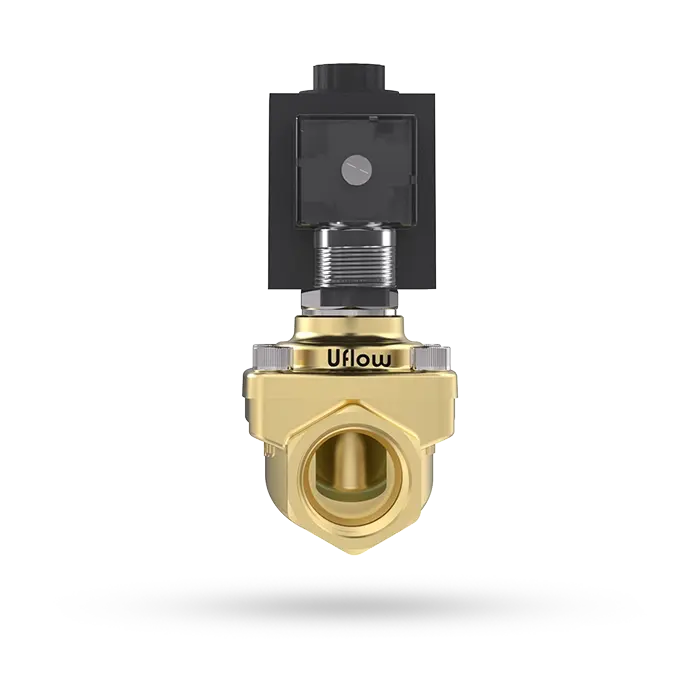

Coil Features

High Reliability Unaffected by Voltage Surges. Easy coil changes coil lockable in 4X90 position or freely movable in between as require.

Coil Housing

IP65 Epoxy square coil

Note

Use of filter in the inlet port is recommended.

| Model No. | Body Material | Pipe (Inch) | Orifice (mm) | Min. Operating Pressure Kg/cm² | Max. Operating Pressure Kg/cm² | Seal & Diaphragm Material | Flow Factor Kv m³ / hr |

|---|---|---|---|---|---|---|---|

| PBU-2Y | BRASS | ½” | 15 | 1.5 | 40 | PUR | 3550 |

| PBU-3Y | BRASS | ¾” | 15 | 1.5 | 40 | PUR | 3550 |

- High Switching Cycle

- Blow Molding Equipment

- Fast Response Time

- High Pressure

- Higher Service Life

- PUR Diaphragm

- Inbuilt Filter

- Reduce Unnecessary Volume Inside the Pilot Chamber

- Minimal Disruption of Response Time

| Model No.. | Port Size | Diagram No. | A | B | C | D | E | F |

|---|---|---|---|---|---|---|---|---|

| PBU-2Y | ½” | 17.1 | 80 | 119 | 101 | 54 | 40 | 76 |

| PBU-3Y | ¾” | 17.1 | 80 | 119 | 101 | 54 | 40 | 76 |