Technical Data

| Cylinder bore Ø (mm) | 32 | 40 | 50 | 63 | 80 | 100 | 125 |

| Cushion stroke (mm) | 21 | 23 | 23 | 23 | 28 | 28 | 40 |

| Standard strokes (mm) | 25, 50, 80, 100, 125, 160, 200, 250, 300, 320, 400, 500 | 50, 80, 100, 125, 160, 200,250, 300, 320, 400, 500 | |||||

Media

Compressed air - filtered - lubricated

Working pressure

0.5 - 10 bar

Medium temperature

| Regular | High temperature applications |

| +5°C to +60°C | +5°C to +150°C Max |

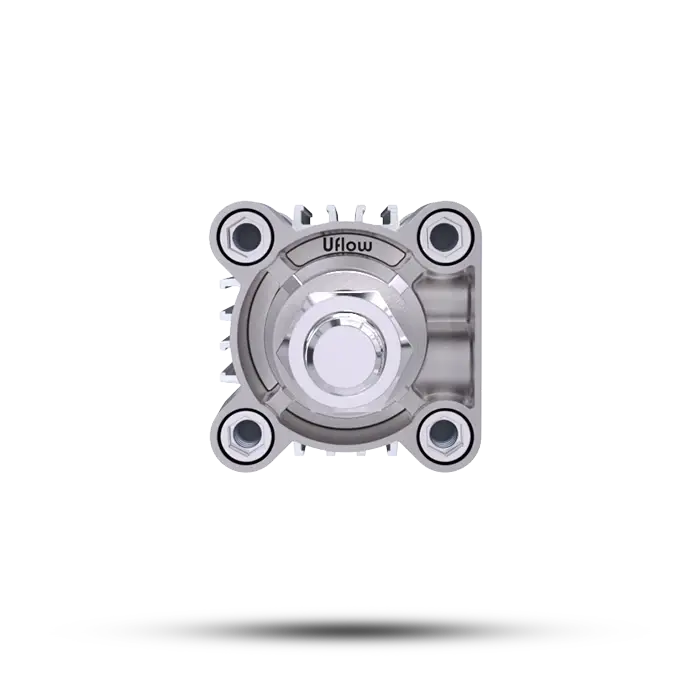

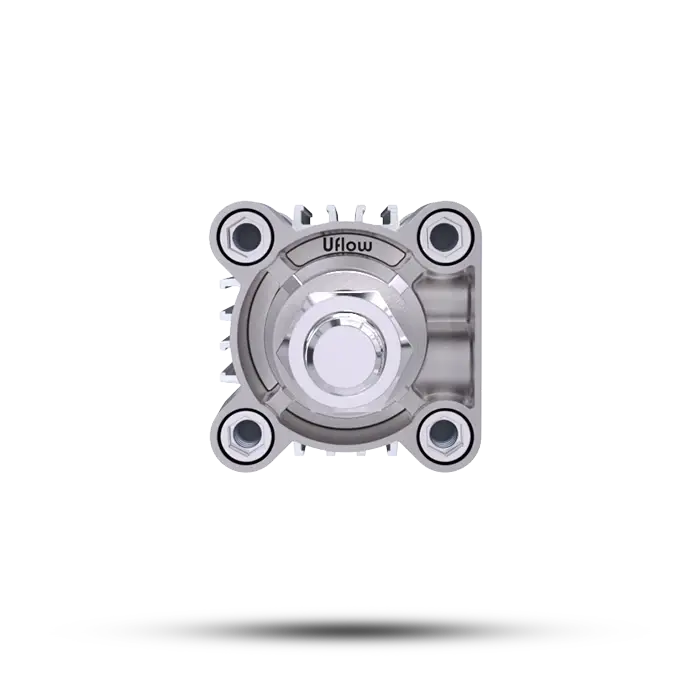

Materials of Construction

Aluminium, Brass, Steel, Acetal, Polyurethane, Nitrile (Regular), FKM (High temperature)

Mountings

Foot Mounting, Front / Rear Flange, Male Clevis, Female Clevis,Center Trunnion, Front Trunnion , Rear Trunnion

Accessories

Clevis Foot Bracket, Wall Mounting Bracket, Trunnion Bracket, Rod End Fork, Rod End Aligner, Rod End Spherical Eye

Ambient Temperature

-10°C to +70°C